التميّز

قطع معدنية مخصصة مشكّلة بالدلفنة ومُجمّعة

برغل ستيل هي شركة رائدة في توفير قطع معدنية مخصصة مشكّلة بالدلفنة ومُجمّعة لمجموعة واسعة من الصناعات. مع أكثر من 7 سنوات من الخبرة، نحن معروفون بتقديم منتجات عالية الجودة وخدمة عملاء استثنائية.

يستخدم فريقنا من المهندسين والفنيين ذوي الخبرة أحدث التقنيات والمعدات لتصميم وتصنيع قطع معدنية مخصصة تلبي المواصفات الدقيقة لعملائنا.

تصنيع مستدام

عمليات رشيقة تقلل الهدر وتخفض الأثر البيئي.

هندسة دقيقة

تقنيات متطورة لتحقيق المواصفات الدقيقة في كل مرة.

خدمة شاملة

مساعدة في التصميم، نماذج أولية، تجميع، وتسليم في الوقت المحدد.

مبنيّون على الثقة، مدفوعون بالجودة

اكتشف ما يجعل برغل ستيل الشريك المفضّل لقادة الصناعة

مستدامون وملتزمون

ملتزمون بممارسات تصنيع مسؤولة بيئياً. نسعى باستمرار لتقليل بصمتنا البيئية مع الحفاظ على تميّز المنتج.

جودة فائقة

شركة رائدة في القطع المعدنية المشكّلة بالدلفنة مع نظرة ثاقبة للابتكار، نستكشف باستمرار تقنيات جديدة لتحسين قدراتنا.

خبرة عميقة

مع أكثر من 7 سنوات من الخبرة الصناعية العميقة، يجلب فريقنا شغفاً لإنشاء حلول مبتكرة باستخدام عمليات التصنيع الرشيقة.

حلول حديدية لكل صناعة

مجموعة شاملة من منتجات الحديد عالية الجودة المصنّعة بدقة

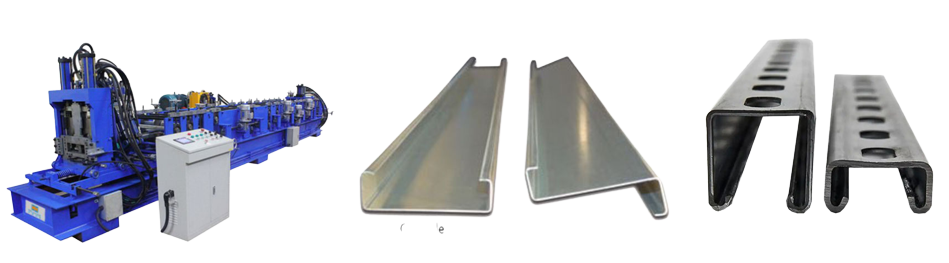

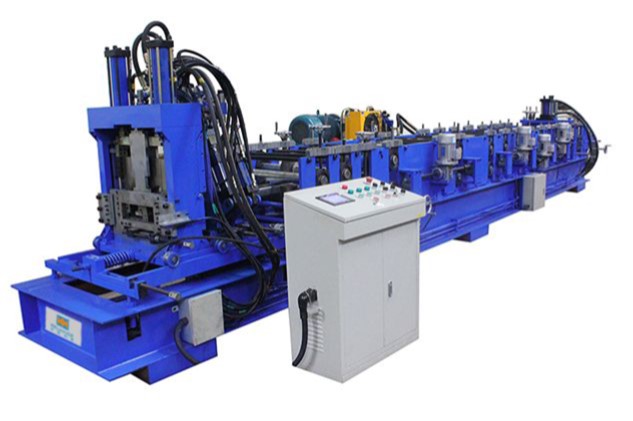

مقاطع مشكّلة بالدلفنة

برغل ستيل هي شركة رائدة في توفير قطع معدنية مخصصة مشكّلة بالدلفنة ومُجمّعة لمجموعة واسعة من الصناعات.

يستخدم فريقنا من المهندسين والفنيين ذوي الخبرة أحدث التقنيات والمعدات لتصميم وتصنيع قطع معدنية مخصصة تلبي المواصفات الدقيقة لعملائنا. سواء كنت بحاجة إلى قوس بسيط أو مكوّن معدني معقد، يمكننا إنتاجه بدقة وكفاءة.

نحن نفخر بعمليات التصنيع الرشيقة لدينا، والتي تتيح لنا تقليل الهدر وزيادة الكفاءة وخفض التكاليف مع الحفاظ على الممارسات المستدامة.

- تقنية تشكيل بالدلفنة عالية الدقة

- تصاميم مخصصة وفق المواصفات الدقيقة

- عمليات تصنيع رشيقة

- مساعدة في التصميم والنماذج الأولية

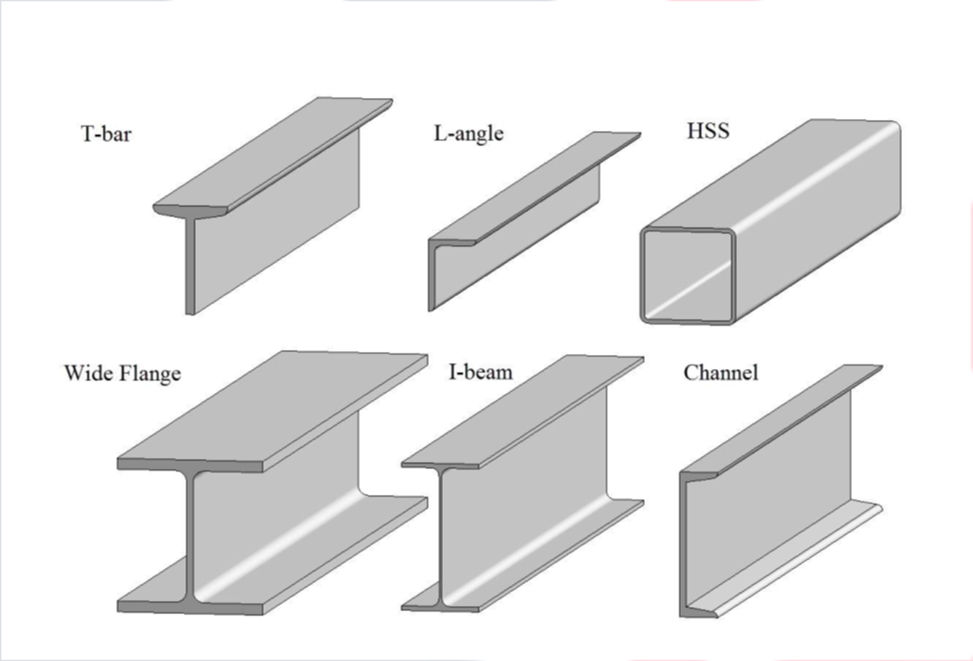

مقاطع مدلفنة على الساخن

مقاطع IPE و HEA و UPE هي مقاطع فولاذية مدلفنة على الساخن تُستخدم بشكل شائع في تطبيقات البناء والصناعة.

يتم إنتاج هذه المقاطع عن طريق تسخين كتلة فولاذية إلى درجة حرارة عالية ثم تمريرها عبر سلسلة من البكرات لتشكيلها إلى المقطع العرضي المطلوب. يمكن ضبط البكرات لإنتاج مقاطع بأحجام وأشكال مختلفة.

من أهم مزايا المقاطع الفولاذية المدلفنة على الساخن قوتها ومتانتها العالية — القادرة على تحمل أحمال عالية ومثالية لمشاريع البناء واسعة النطاق.

- مقاطع IPE و HEA و UPE متوفرة

- قوة ومتانة عالية

- أحجام وأشكال مخصصة متنوعة

- مثالية للبناء واسع النطاق

ألواح مموّجة

الألواح المموّجة هي مادة تسقيف شائعة يتم إنتاجها باستخدام عملية تشكيل بالدلفنة المتقدمة.

تتضمن العملية تمرير صفيحة معدنية مسطحة عبر سلسلة من البكرات لإنشاء نتوءات وأخاديد، مما يمنح الصفيحة شكلها المموّج المميز — الذي يوفر صلابة إضافية وتصريف ممتاز للمياه.

الألواح المموّجة متعددة الاستخدامات ويمكن تخصيصها بمجموعة من الألوان والتشطيبات، مطلية أو مغلفة لحماية إضافية ضد الصدأ والتآكل.

- عملية تشكيل بالدلفنة متقدمة

- صلابة وقوة فائقة

- ألوان وتشطيبات مخصصة

- مقاومة للصدأ والتآكل

فولاذ خفيف القياس

الفولاذ خفيف القياس هو نوع من الفولاذ المشكّل على البارد يُستخدم بشكل شائع في البناء الحديث وبناء المنازل.

على الرغم من سماكته الرقيقة، فإن الفولاذ خفيف القياس مقاوم بشكل كبير للانحناء والكسر، مما يجعله مثالياً للجدران الحاملة وأنظمة التسقيف والمكونات الهيكلية الأخرى.

يُستخدم أيضاً بشكل شائع لمكونات المباني مسبقة الصنع التي يمكن نقلها وتجميعها بسهولة في الموقع، مما يقلل وقت البناء والهدر.

- مشكّل على البارد لأقصى قوة

- مثالي للبناء الحديث

- بديل اقتصادي فعّال

- مكونات مسبقة الصنع متوفرة

مستعد لبدء مشروعك القادم؟

تواصل مع فريقنا للحصول على استشارة مجانية وعرض سعر مخصص لاحتياجاتك من تصنيع المعادن.

القيادة

تعرّف على صاحب الرؤية وراء برغل ستيل

بشار برغل

الرئيس التنفيذياتصل بنا

يسعدنا مساعدتك في بدء مشروعك القادم